Elektrilised vastukaalutõstukid

Vastukaalutõstuk on ideaalne lahendus raskemate koormate käsitsemisel. Tööpõhimõte seisneb kahvlitel asetseva koorma ning tõstuki tagaosa raskuse omavahelises tasakaalustamises, mis suurendab stabiilsust ja juhi ohutust. Tootevalikus olevad elektrilised CB-d on saadaval erineva aku võimsusega ning tõstevõimega kuni 8 t. Kuna seadmed töötavad aku jõul, sobivad need ideaalselt nii sise- kui ka välistingimuses kasutamiseks.

Find your next electric forklift truck

Let us guide you through 6 simple steps

We will help you find the best electric counterbalanced forklift for your business, with the help of the following steps:

- Driving

- Load handling

- Load carrier

- Manoeuvring

- Lifting

- Special requirements

Take the guide and find out which electric truck is your best match!

Helping forklift operators minimise collisions while reversing

Want to increase safety in your warehouse? Your new counterbalanced forklift can be equipped with our Operator Assist System SEnS+ (Smart Environment Sensor), for optimising material handling safety whilst minimising the risk of incidents and damage costs.

How it works:

- A stereoscopic camera module detects pedestrians and objects behind the forklift while reversing.

- SEnS+ provides audible and visual alerts and applies truck traveling speed restrictions depending on the detection risk.

- At standstill, start motion prevention limits the truck's starting movement if an obstacle is detected.

- The system includes dynamic range detection, taking truck speed and turning angle into account to automatically adjust the detection area.

Truck stability

System of Active Stability

Toyota SAS is fitted as standard on the entire Toyota Traigo family. SAS actively contributes to workplace safety by protecting your operators, your goods and trucks while reducing operational cost.

- SAS Mast Control defines the optimised mast speed and angle to guarantee safe goods handling.

- SAS Fork Levelling Control adjusts the forks to the desired level just by pushing a button.

- SAS Swing Lock Cylinder (on 4-wheel range) ensures stability when taking curves to protect operators without compromising on productivity. On the 3-wheel range, SAS optimises the driving speed when taking curves.

- SAS Steering Synchroniser automatically aligns the steering wheel knob with the position of the rear wheels, offering higher ergonomics.

FAQ & helpful insights

Here we have gathered frequent questions and answers about electric counterbalanced trucks to help you find your next electric truck.

Operating electric counterbalanced forklifts

Elektritõstukite mõned paljudest eelistest on:

- Puuduvad heitgaasid

- Madalamad pikaajalised kulud Li-ion akudega

- Li-ion akudel puudub hooldusvajadus

- Saab kasutada nii sise- kui välistingimustes

Jah, kuna elektritõstukitel puuduvad kahjulikud heitgaasid, siis võibb neid kasutada nii sise- kui välistingimustes.

Lao- ja tootmisruumides on üldjuhul tasased nin siledad põrandad, mida saab hoida puhtana kasutades mittemäärivaid rehve. Eriti oluline on see kõrgendatud hügieeni nõuetega kasutuskohtades nagu toidu- ja farmaatsiatööstus.

Kindlasti võib elektriliste vastukaalutõstukitega töötada nii sise- kui välistingimustes. Välistingimuste jaoks on vaja vastupidavat ja stabiilset tõstukit, mis suudab töötada erinevates tingimustes:

- Ebatasane pind

- Porised teed

- Märg betoon

4-rattaline elektritõstuk kinnise kabiiniga on stabiilne ja kaitseb tõstukijuhti ka märgades tingimustes töötamisel.

Ebatased või kahjustatud põrandad muudavad sõitmise ebamugavaks ja võivad põhjustada koorma libisemist. Hoides põrandad heas korras suureneb tootlikkus ja tõstukijuhtide mugavus ning vähenevad kulud.

Jah, kaldpindadel tuleb olla eriti ettevaatlik. Koormaga sõites peab koorem olema alati ülesmäge ning samal ajal tuleb olla ohutus kauguses kallaku äärest, et vältida ümberminekut.

Toyota elektritõstukid on saadaval järgmiste akudega:

- happeakud

- Li-ion akud

- kütuseelemendid

Li-ion akusid saab laadida igal hetkel, kui tõstukit ei kasutata, näiteks puhkepauside ajal. Happeakudel on samas piiratud hulk laadimistsükleid ja need tuleb alati ühe korraga täis laadida nin mitte lasta tühjeneda alla 20%.

Load handling and pallet stacking

Loads come in different sizes. Length and width help you define the right load carrier. The longer the load, the larger the load centre. The load dimensions may affect the lift capacity of your forklift and limitations in aisle width.

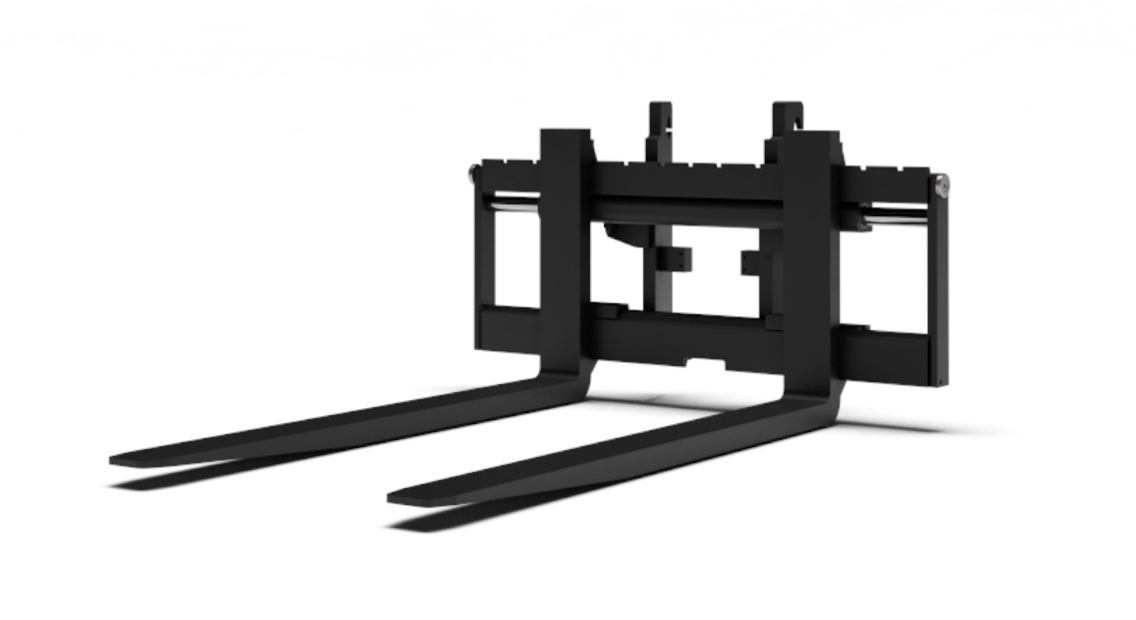

- A forkpositioner or forkspreader allows to spread the forks, to adjust to different pallets/load carrier sizes.

- Forkpositioner have impact on the load capacity and aisle width.

- The sideshift function can be integrated for even more efficient load handling and precision.

Külgnihe on laialt kasutatav tõstukite lisaseade, mis võimaldab kahvleid liigutada paremale või vasakule ilma tõstukiga manööverdamata, muutes sellega töö kiiremaks. Külgnihe mõjutab tõstuki tõstevõimet ja töökoridori laiust.

Pallet overhang occurs when goods are larger than the pallet. This can cause load damage. The right size of load carrier or better goods placement on the pallet will improve the handling by forklift.

- Pallets are still the most popular load carriers for goods transport with forklifts.

- The most common wooden pallet size used in Europe is 1200 x 800 mm, allowing 4-way entry. There are also 2-way entry pallets.Not all industrial forklift truck types are compatible with all types of pallets – be sure to check pallet dimensions and load size (including overhang) before specifying your requirements on forks.

- Sizes of pallets often vary from country to country, depending on usage.

Aisle width and forklift manoeuvring

Calculation differs depending on the model; the specifications that need to be taken into account to calculate the aisle width (Ast) are:

- Turning radius (Wa): the minimum radius a forklift needs to turn in circle.

- Load dimensions: the width (b12) and length (l6) of the load define the space needed for the truck to place the load.

- Load distance (x): the horizontal distance from the centre of the front wheels to the front of the forks.

- Safety clearance (a): 200 mm for safer navigating in aisles.

Vahekoridori laius on minimaalne ruum, mida tõstukil on vaja, et pöörata riiulite vahel risti kauba riiulisse panemiseks või sealt võtmiseks.

A great benefit of 3-wheel forklifts is their manoeuvrability, thanks to a shorter turning radius. Comparing a Toyota 3-wheel with a 4-wheel 48 V model, the difference in turning radius is about 140mm. Going for a compact 3-wheel, will reduce the turning radius even further by about 100 mm.

A great benefit of 3-wheel forklifts is their manoeuvrability, thanks to a shorter turning radius. Comparing a Toyota 3-wheel with a 4-wheel 48 V model, the difference in turning radius is about 140mm. Going for a compact 3-wheel, will reduce the turning radius even further by about 100 mm.

Aisle width data is mentioned in the data sheet of each forklift, allowing to compare models and find the best match for your operation.

The extra 200 mm safety margin will help to ensure the operator has enough space to turn safely in the aisle.

Lifting pallets with an electric truck

To know maximum lift height, find out the height of the highest racking beam and add 150-200 mm to give the operator some extra manoeuvring space to place the load.

A forklift truck will state its load capacity, or nominal capacity. This is calculated as the maximum weight it can raise to a pre-determined height, when its load centre is at a certain point. The load centre is the horizontal distance from the vertical face of the forks to the centre of gravity of the load. Standard load centres vary depending on the nominal capacity of the forklift, and will be one of the following:

- 0 – 1,000 kg: 400 mm

- 1,001 – 5,000 kg: 500 mm

- 5,001 – 10,000 kg: 600 mm

A forklift truck’s load capacity or nominal capacity is calculated as the maximum weight it can raise to a pre-determined height, when its load centre is at a certain point. If the load needs to be lifted above that height, or the load centre is further away, then the capacity will be lowered. That’s what residual capacity is: the actual lifting ability in a given situation, which may be less than the nominal capacity.

Either the forklift roof height or collapsed mast height will define which is the lowest height it can go under. Pay attention, when the forks are raised with a non free-lift mast, the inner mast section will lift as soon forks go up, influencing the lowest passing point.

Forklift attachments add extra weight and extend the load distance, reducing the load capacity.

Forklift attachments add extra weight and extend the load distance, reducing the load capacity.

Applications with special requirements

Working in dust or wet environment might affect the proper functioning of forklifts and require more frequent servicing and repair. Trucks with high level of dust- and water protection are recommended for these environments.

To run several shifts, you need a forklift for intensive use with little time to refill. Electric counterbalanced trucks are clean and productive machines for indoor and outdoor use. In combination with lithium-ion batteries, they can be recharged quickly at any time, to keep going.

To run several shifts, you need a forklift for intensive use with little time to refill. Electric counterbalanced trucks are clean and productive machines for indoor and outdoor use. In combination with lithium-ion batteries, they can be recharged quickly at any time, to keep going.

For working in hazardous or explosive environments, explosion proof forklifts should be used. The truck is adapted so no components can create sparks.

Cold store operations are one of the toughest working environments. Sub-zero temperatures affect your trucks’ battery capacity, electronics and lubrication. To prevent breakdown and repair costs, dedicated cold store trucks are highly recommended. Depending on the model, the trucks are additionally fitted with components such as cold store oil, stainless steel axles...

When selecting a forklift truck, you should verify if the model is capable of operating on the gradients you have on your site. The gradeability rating can be found in the truck’s data sheet. The maximum gradeability is the maximum grade a forklift can climb for a short period. Not only the ability to climb a slope is important, but also safely descending it when loaded.

When selecting a forklift truck, you should verify if the model is capable of operating on the gradients you have on your site. The gradeability rating can be found in the truck’s data sheet. The maximum gradeability is the maximum grade a forklift can climb for a short period. Not only the ability to climb a slope is important, but also safely descending it when loaded.